ENVIRONMENTAL MANAGEMENT SYSTEM

With the principle of “efficient use of resources,” Aksa Energy runs its operations in an environmentally-conscious manner for a sustainable future and aims to continuously improve its sustainability performance. The Company strives to make a difference in the sector through its efforts to minimize the environmental effects of energy generation operations, as well as through environmental management practices that cover every step of the value chain.

Aksa Energy has adopted an Environmental Policy to ensure that this understanding is institutionalized and embraced by all stakeholders. The Environmental Policy of Aksa Energy is based on four main pillars: climate change, natural resource management, waste management and conservation of biodiversity.

Aksa Energy’s Environmental Policy ensures regularly reporting, monitoring, and communication of the Company’s performance towards its sustainability goals, based on efficiency, transparency, stakeholder engagement, and cooperation. While carrying out the business activities, Aksa Energy takes great care to use natural resources efficiently, reduce greenhouse gas and air emissions, minimize waste generation, and preserve biodiversity.

Establishing a Framework Environmental Management System in order to determine the objectives and targets related to the Environmental policy, and to manage, monitor and control the activities in accordance with this policy, the Company holds the following certifications: ISO 14001 Environmental Management System, ISO 9001 Quality Management System, ISO 50001 Energy Management System, ISO/IEC 27001:2013 Information Security Management System* and ISO 45001 Occupational Health and Safety Management System. In addition to the headquarters, Bolu Göynük Thermal Power Plant and Şanlıurfa Natural Gas Combined Cycle Power Plant are also within the scope of ISO/IEC 27001:2013 Information Security Management System.

In October 2017, the Company initiated efforts to extend the Integrated Management Systems practices (ISO 9001 Quality Management System, ISO 14001 Environmental Management System, ISO 50001 Energy Management System and ISO 45001 Occupational Health and Safety Management System), which are already in effect at the Headquarters, to the power plants. This initiative started with Ali Metin Kazancı Antalya Natural Gas Combined Cycle Power Plant and Bolu Göynük Thermal Power Plant. As of the end of 2019, the documentation process was completed, and at the beginning of 2020, the documentation and action management of all systems were transferred to the online document management system. Thanks to this system, which allows remote control and management of the management systems, the works have continued without interruption. The coordination and construction of this system in domestic power plants continue under the leadership of the QHSE (Health, Education, Environment-Quality) department at the Company Headquarters. In 2021, the QHSE team continues to work to implement this system at power plants abroad. As of 2020, activities in Ghana Heavy Fuel Oil Power Plant has commenced within the scope of ISO 14001 Environmental Management System and ISO 45001 OHS Management System.

AIR EMISSIONS

One of the most significant areas of environmental impact within energy generation is air emissions. Aksa Energy regularly monitors and measures the effect of its operations on air quality and ensures that its emissions fall within the legally prescribed limits. The Company makes necessary technological and capital investments to eliminate any adverse impact of the air emissions on the environment and human health. With the continuous emission monitoring systems built in its plants, Aksa Energy instantly tracks emissions and makes sure air emissions from domestic plants are monitored online by the Turkish Republic Ministry of Environment and Urbanization.

To this end, Aksa Energy established a fluidized bed combustion system and wet flue gas treatment system in Bolu Göynük Thermal Power Plant.Thanks to this system, the power plant reached the legal emission target set by the EU for the year 2018 in 2015. In addition, Bolu Göynük Thermal Power Plant’s NOx emission volume has been reduced to a low level by using fluidized bed combustion technology with limestone injection. Similarly, the gas turbines with ultra-low NOx emission combustion systems at Ali Metin Kazancı Antalya Natural Gas Combined Cycle Power Plant and the flue gas treatment system to reduce SOx emissions at Northern Cyprus Kalecik Fuel Oil Power Plant are critical for reducing air emissions.

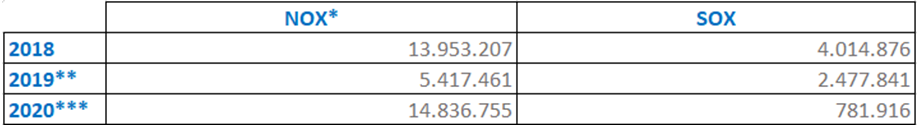

* Indicates the amount in NO2.

** The decrease in the number of stop/startups at Aksa Energy plants effectively reduced air emissions in 2019.

*** The increase in the annual total operating time at our Ghana HFO Power Plant was effective in the increase in NOx amount in 2020. Various studies will be carried out in order to reduce the relevant values in the upcoming period.

WASTE MANAGEMENT

Waste management is one of the most important components of Aksa Energy’s environmental sustainability approach. The Company conducts research studies to reduce the amount of waste and boost business process efficiency in order to achieve a higher performance level each year. Efforts are expended to improve business processes, reduce resource consumption, and decrease waste generation by using innovative technologies and resources effectively.

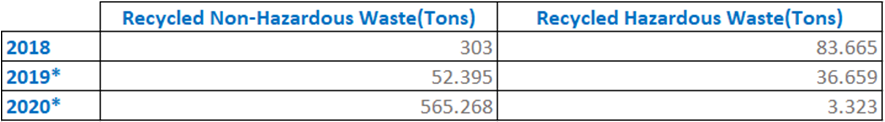

The Company disposes of all its wastes in keeping with applicable laws, rules and regulations, and in line with its Environmental Policy. Aksa Energy’s activities to recycle hazardous and non-hazardous waste from production processes are carried out in the periods specified in the Waste Management Regulation. Hazardous waste released by the operation processes is stored in temporary waste storage areas on the plant sites, where its contact with the external environment is cut off to prevent jeopardizing human health and the environment. Later, these materials are transported in licensed vehicles to recycling or disposal facilities, at regular intervals. Packaging waste is sent to recycling companies contracted by municipalities in the regions where the facilities are located. Aksa Energy had 3,323 tons of hazardous waste recycled in 2020.

The ashes from the Bolu Göynük Thermal Power Plant were completed in 2017 instead of the temporary ash storage area, and started to be stored in the Southern Ash Regular Storage Area, for which environmental permit was obtained from the Provincial Directorate of Environment and Urbanization. More than 6,000 saplings were planted around the plant site prior to the commissioning of the power plant.

As a result of the importance Aksa Energy attaches to waste management and the works it has carried out in this context, Antalya Ali Metin Kazancı Antalya Natural Gas Combined Cycle Power Plant and Bolu Göynük Thermal Power Plant have been awarded the "Zero Waste" Certificate in January 2021.

* The increase in the amount of Recycled Non-Hazardous Waste in 2019 mostly comes from the recycling of scrap material remaining from the construction phase at the Ghana Heavy Fuel Oil Power Plant site.

WATER AND WASTE WATER MANAGEMENT

Water resources are crucial among the decreasing natural resources due to many factors affecting the whole world such as climate change and urban migration. Against this backdrop, Aksa Energy aims to minimize water consumption in all its business operations and processes.

The Company, which shapes its operations with an effective management system to minimize water consumption, also carries out its activities with an innovative approach.

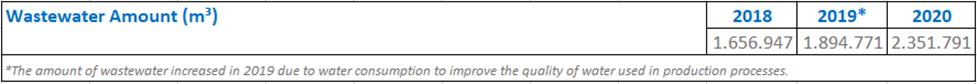

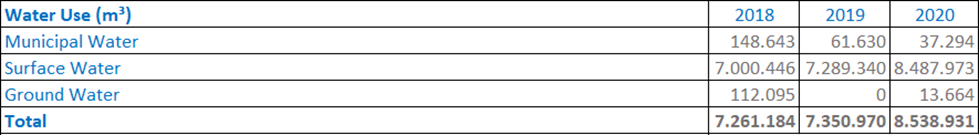

Aksa Energy uses water from varied resources such as municipal water supply, surface water and groundwater, depending on the region where it operates. The Company ensures that wastewater from its operations is analyzed by accredited laboratories and discharged pursuant to the Water Pollution Control Regulation.

In 2020, the amount of municipal water consumption decreased by %39 compared to 2019.

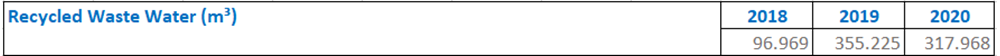

In 2020, with decarbonization facilities more than 317,968 m³ of water was saved in Ali Metin Kazancı Antalya Natural Gas Combined Cycle Power Plant and 1.5 million m³ in Bolu Göynük Thermal Power Plant.

In addition to this method at Bolu Göynük Thermal Power Plant, the Company reverses osmosis wastewater technology to collect wastewater in a different pool and reuses it for as humidification. Moreover, Aks Energy created Çatak Pond with a TRY 17.5 million investment to meet the power plant’s water requirement. The regional community also benefit from this water resource. The regional community also benefit from this water resource via the General Directorate for State Hydraulic Works.

In addition, a seawater desalination system was installed at Northern Cyprus Kalecik Heavy Fuel Oil Power Plant and it meets 100% of the plant’s water requirements.

Modification of the purifier tank system for seawater treatment, which was revised in 2020, improved the efficiency of internal consumption. The Company also purifies wastewater by evaporating and condensing it with the Evaporator Treatment System for natural gas closed-cycle systems and internal needs.At Ghana Heavy Fuel Oil Power Plant in Africa, where water resources are more limited, Aksa Energy has built measurement tools to monitor water consumption. The Company also uses the wastewater discharged from the power plant’s water-softening unit for garden irrigation purposes.

BIODIVERSITY

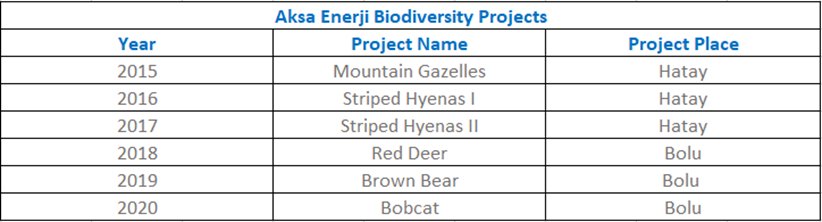

Aksa Energy continues its operations with an approach that takes into account possible environmental impacts on species living in its areas of operation. The Company regularly monitors, evaluates and reports the impact of its operations on biodiversity. In this context, Aksa Energy cooperated with Hatay Nature Conservation Association (TAKODER) from 2015 to 2021.

Within the scope of this collaboration, Aksa Energy first sponsored a Conservation Project for Hatay Mountain Gazelles to support conservation of the mountain gazelles and their habitats in Turkey. Afterwards, the Company contributed to the project for the determination of the current status of the striped hyenas residing nearby Kırıkhan Gölbaşı village in Hatay and obtaining information about living spaces and their ecology in 2016 and 2017. Photo- traps were placed in the animals’ habitats to be able to observe the striped hyenas. Thanks to this initiative, it was also confirmed that the rock gerbil (Gerbillus dasyurus), which was thought to be extinct, still lived in Turkey.

As part of the project undertaken in cooperation with TAKODER in 2018, a study was carried out to determine the presence and ecology of red deer (Cervus ephalus) in the vicinity of Yedigöller National Park. The project helped identify the species’ population size and density, distribution, habitat, nutrition and food resources, social behavior, relationship with humans, and the elements that pose a threat to the species, as well as the measures to be taken to protect them. The study also presented notes to raise awareness among the public and to preserve and sustain the population of red deer, the symbol of the region’s biological diversity.

In 2019, Aksa Energy initiated activities in Bolu for the conservation of brown bears (Ursus arctos), the biggest predator and the only bear species living in Turkey. This initiative aimed to identify the threatening factors in the geographic areas that the species inhabits while establishing protection measures in the Yedigöller region of Bolu province to preserve species in the region and to raise awareness among the public. Informational signage was planned to be placed in road networks and areas where tourism activities are conducted; and ecological bridge passages were identified. Additionally, measures taken to protect the species were reported to the Bolu Branch of the Nature Conservation and National Parks.

Adding a new initiative to its protection of biodiversity in 2020, Aksa Energy carried out a project in Bolu, where it operates, for the bobcat (Lynx lynx). Within the scope of the project, the Company focused on the lynx species, which is threatened according to the International Union for Conservation of Nature (IUCN) Mediterranean Biodiversity assessment, and contributed to analysis to identify the factors that threaten the species and set forth protection recommendations. During the project, carried out to contribute to the sustainability of these lynxes – rare in Turkey and generally found in Bolu – other species were determined, and various ecological data collected. That these lynxes still inhabit relevant region is an indication that the ecosystem is functioning properly.

Aksa Energy will examine the habitation areas of Mediterranean Monk Seals in Northern Cyprus coastal area in 2021. The breeding, sheltering and roaming areas of seals in this zone will be identified and mapped.

To promote the participation of stakeholders in environmental issues and to fulfill our commitment related to the environment, you are welcome to share your suggestions and views with us via enerji@aksaenerji.com.tr.